Protecting organoid technology in Europe

The FDA recently announced its plans to replace animal testing in the development of monoclonal antibodies with other methods, including human organoid models.

We’re following up with a two-part series on recent updates to the field of organoid technologies:

Part one: Findings announced at the University of Cambridge’s first Human Organoid Symposium on 28 March, 2025

Part two: Exploring how companies can and are protecting organoid technology in patent filings

For insights into patent filing trends in the field of organoids, read our previous article.

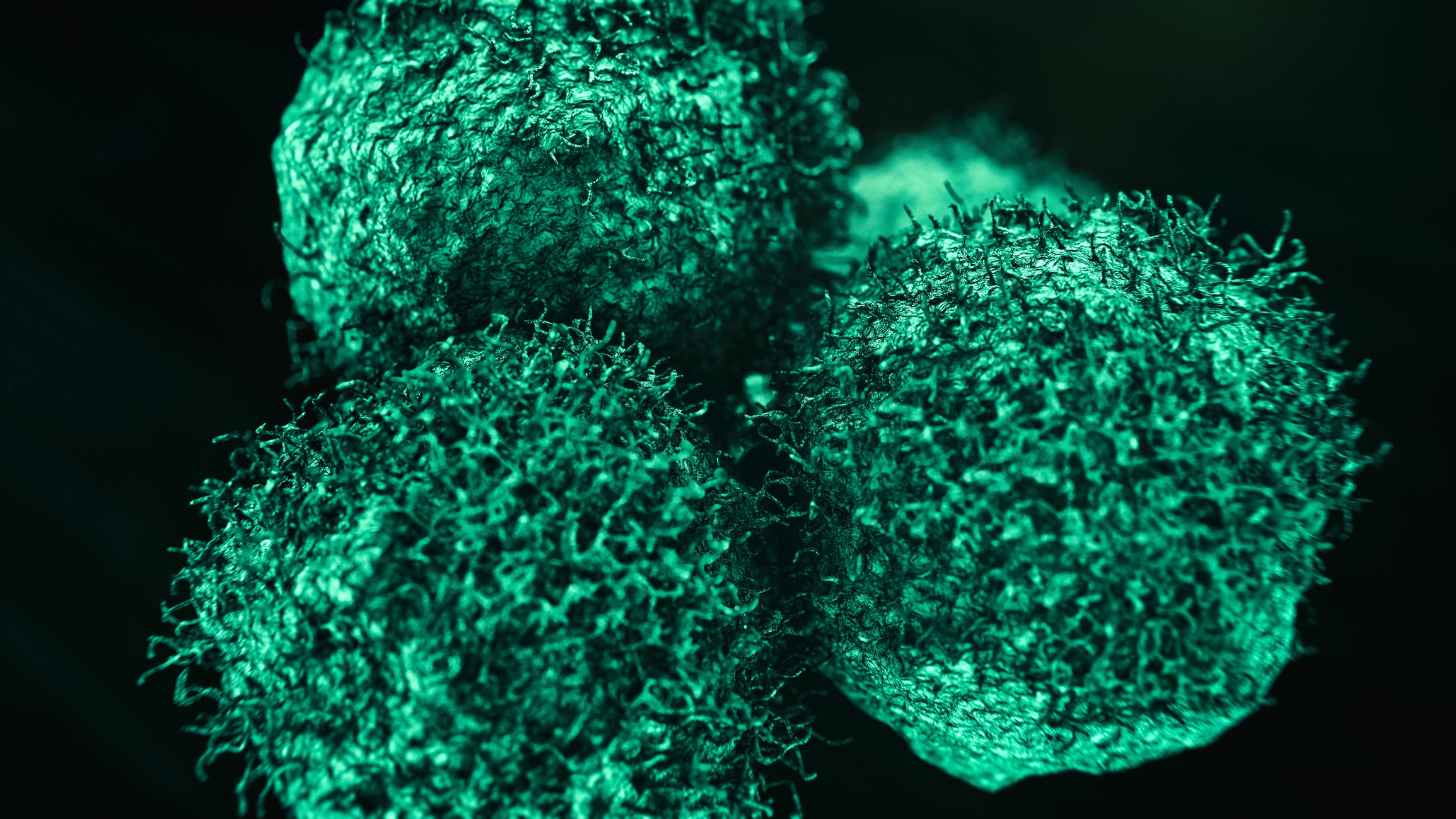

An organoid is a 3D, stem cell derived, miniaturised and simplified model of an organ produced in vitro that mimics the key functional, structural, and biological complexity of that organ. They have diverse applications, from mechanistic studies of tissue development to disease modelling and regenerative medicine.

Organoids per se

To achieve broad protection, it is highly desirable to obtain granted product claims towards the organoid itself. These can be obtained through product by process claims, such as the foundational patents granted to Koninklijke Nederlandse Akademie van Wetenschappen and HUB Organoids (recently acquired by Merck) for a variety of 3D tissue organoids obtainable by the use of specific culture media (e.g. EP2393917B1, EP3061808B1, EP2598633B1).

Alternatively, the claimed product can be distinguished by the inclusion of (or absence of) a distinguishing feature. EP3215603B1 and EP2970896B1 specify that the organoids are “scaffold free.” Organovo distinguishes itself from competitors by generating organoids using a bioprinting method to achieve scaffold free organoids from skin (EP3215603B1) and liver (EP2970896B1). Achieving scaffold free organoids allows for the transplantation of tissue “patches” into recipients for therapy, which may otherwise elicit adverse host responses to the scaffolds.

Use of the organoid

One of the key industrial applications of organoids is their use in high throughput drug screening. This application can be formulated into a method claim. For example, Organovo’s EP3519558B1 relates to a screening method comprising contacting a 3D bioprinted renal tubule model with a potential toxic agent and a candidate therapeutic agent, and assessing the ability of the candidate therapeutic agent to reverse, reduce or prevent renal injury by the potential toxic agent.

Organoids can be used as a cell source for “organ-on-a-chip” systems (microfluidic devices that simulate the activities, mechanics and physiological response of an entire organ or an organ system). Organoids lack some critical elements of the in vivo microenvironment, such as the presence of vasculature and more specialised organ physiology such as the mechanical forces caused by fluid flow and peristalsis in intestinal models. Integrating such systems replicate physiological organ flow environments and enhance differentiation and maturation consistency of organ-characteristic cell types. These systems may be protected by claims towards the microfluidic device per se (e.g. TissUse GmbH’s EP3548606B1 and Emulate’s EP3728561B1) as well as methods of use.

Consumables, supports, and methods for culturing and/or obtaining organoids

As discussed above, organoids are stem cell derived. As discussed previously, one of the challenges of working with stem cells is that their stemness and differentiation potential can be altered, or lost, when removed from their in vivo environment and studied or otherwise used in vitro. This is because their local environment in vivo is highly complex (e.g. relying on complex cell-cell interactions, cytokine gradients, oxygen levels), which can be difficult to replicate in vitro. The necessary environment for organoid growth is mainly provided for by culture media and scaffolds. The individual components of the in vitro environment (e.g. consumables, supports) can be protected individually or together, as a system.

Culture media provides nutrition and directs differentiation of the stem cells into specialised cells. Essential components of the culture media can be protected, e.g. Koninklijke Nederlandse Akademie van Wetenschappen’s EP2718422B1 requires the presence of an Lgr5 agonist, BMP inhibitor and one or more TGF-beta inhibitor in the culture medium.

Biomatrix scaffolds on the other hand, mimic the mechanical and biochemical properties of tissues, and offer a supportive environment for cells to organize into complex 3D structures. Scaffolds are usually hydrogel based, which refers to a 3D network of hydrophilic polymers that undergo a significant volume phase transition or gel-solution phase transition in response to certain physical and chemical stimuli.

Patents are also granted towards methods for culturing and/or obtaining the organoids which recite the specific conditions used. For example, the method of EP3344753B1 requires the use of a hydrogel wherein the specific mechanical and biochemical properties of the hydrogel are recited (i.e. the bioactive molecule is laminin-111 and the hydrogel has a shear modulus between 0.05-0.5 kPa). EP3430132B1 relates to a method of deriving and maintaining a midbrain-like organoid using a culture medium comprising various cytokines and protein inhibitors.

Device components, such as a microvalve for use in a microfluidic device are also protectable and is the subject of GB2583059B in the name of CN Bio, a Cambridge based company which makes organ-on-a-chip systems compatible with organoids.

Fabrication and assembly techniques

Bioprinting technology has revolutionised tissue engineering by allowing the fabrication of biologically functional tissue by precisely arranging cells and biomaterials in 3D space. Bioprinting organoids involves the layer-by-layer printing of bioink (typically comprising cells, biomaterials, and growth factors) according to a predefined structure, followed by in vitro culture and induction to form organoids with specific functions. As discussed previously, trends in patent filings towards bioprinting technology show an increase in bioinks in recent years relative to bioprinting methodologies per se. This indicates that bioprinting techniques have become somewhat established and that global innovation is more focused on materials for organ or tissue-specific customisation. Like the thermoplastics that are often utilized in traditional 3D printing, bio-inks can be extruded through printing nozzles or needles into filaments that can maintain its shape fidelity after deposition. However, as bioinks contain living cells, the bioinks are sensitive to the normal 3D printing conditions and must contain specific rheological, mechanical, biofunctional and biocompatibility properties.

As with culturing consumables, patents can be obtained by protecting a necessary component of the bioprinting process. EP4249008B1, EP4121464B1 and EP4003439B1 are examples of collagen and/or gelatin based bioinks necessary to obtain the generated organoid through bioprinting.

Alternatively, methods directed towards the process itself can be obtained. For example, EP3126490B1 refers to a method of fabricating an organoid.

Summary

In summary, several layers of protection can be obtained for organoid technology in Europe, which together can give broad coverage for the subject matter. Whilst this article is focused on the patentability of organoids in Europe, scope of protection is likely to be different in other territories, such as the US.

Oliver Herd, Trainee Patent Attorney, Appleyard Lees